You cannot "freestyle" splices in the manner you are talking, you must use listed products, which those cheapie butt splices probably won't be.

#Splice extension cord full

This family of lights uses all 120v wiring which means the full weight of NEC applies. As a result, no splicing needs to be attempted.ĮDIT: This is obviously NOT a duplicate question as erroneously suggested as "What size heat shrink tube is required?" and "How can I safely do something?" are completely different questions. Update: This particular line of products now has longer lengths of linking cords available. If you believe there is no way this can be done without a moderate risk of fire, it would be very helpful to hear why you think so. The cables will not be in a place where they can be routinely touched, and if I were to move out of the house, I would take all of this stuff down, except for the first of the linkable fixtures which was installed with a junction box by an electrician (it is controlled by a light switch). I realize there may not be a code-approved way of doing this. Any suggestions for the safest way to do this are welcome. Or I could simple put the spliced areas within junction boxes. I could also run all or some of the cabling through conduits, bracketed against the wall.

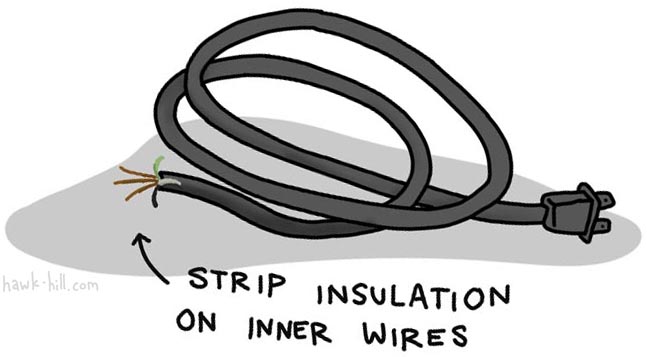

If nothing else, I'll just be using cable staples. The strips will be against the wall, on their mounting brackets, and the cabling can be secured however. Beyond this, what should I do to make sure this setup is safe? I will ensure the splices are solid and the polarity is correct. My plan is to splice them using some 22-18 butt splices, then heat shrink them with 3/4" tubing. I am planning to cut the connector cable in the middle and insert an appropriate extension length from my spool. I have a spool of the same type of cable. The connector cables are 18-2 SPT-2 lamp cord. The connector cables are a bit short for what I have in mind, but I need to use their ends because they have special connectors to link the fixtures and maintain correct polarity. They are linkable LED fixtures which each come with a connector cable to link, optionally, to additional fixtures. The standard crimp splice kits (the automotive kind) are not something you'd want to use except breiefly in an emergency.I am interconnecting some strip lights in a closet. If you don't see the brands I mentioned, take a close look at the splices they do have and you might see one with the same characteristics. Most big box home centers carry the spices and heat shrink. Lowes probably has it, but I haven't looked there. The last time I found the hard heat shrink at Home Depot. I've found one or another of these splices at Lowes and Home Depot. You want that extra length there to provide a bit of stress relief for the cord so that jerking it around in-use won't strain the spliced connections.

For example, if the exposed conductor insulation and their splices is two inches long, you should have at least four inches of hard heat shrink. The total length of the exposed conductors and their insulation should be something that the hard heat shrink tube will cover with an extra inche on either side. NOTE: carefully read the instructions before you begin to prepare the ends. That leaves a splice that's well protected from stress and Hard heat shrink down over all three conductors ahd use the heat gun When you have all three conductors spliced, slide the big piece of.The crimp barrel instead of solder to join the conductors. The Raychem works almost the same except it uses Some plastic sealant at each of its ends to environmentally seal the SolderSleeve splices will melt solder into the joint and also melt Splice's individual heat shrink over the connect and apply heat. Connect each conductor (whether twist or crimp), then slide the.The SolderSleeves require you to twist the ends together. Ra圜hems use a crimp barrel to connect the ends. The splices have you slide on a heat shrink tube before connecting.Pick one that will fit over your cord and make sure it has pieces 4-6 inches long.

If it doesn't look like small black pipe you're looking at the wrong kind. I mean really heavy duty, not the stuff that sort of looks like in flattened tubes in the package. Go to a big box with a good electrical department and look for Ra圜hem or SolderSleeve butt splices, and some heavy duty heat shrink.

0 kommentar(er)

0 kommentar(er)